Rock Processing Solutions. The Knowledge Hub. Crushing chambers. Cone crusher basics in 4 minutes. This is the starting point for understanding how cone crushers work – and

More

The cone crusher is a modified gyratory crusher. The essential difference is that the shorter spindle of the cone crusher is not suspended, as in the gyratory, but is supported in a

More

Sandvik cone crusher series – high performance, low total cost. Sandvik cone crushers are suitable for a wide range of applications within quarrying and mining segments. End

More

2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing

More

Sandvik crushing and screening equipment. Unrivaled jaw crushers, cone crushers, gyratory crushers, impact crushers and more for mining and construction applications.

More

2021年8月15日 Evertsson (1998) combined a process model that describes the flow and breakage of rocks in a cone crusher with raw rock properties to elaborate a crushing

More

2016年1月1日 Compressive crushing has been proven to be one of the most energy efficient principles for breaking rock particles (Schönert, 1979). In this paper the cone

More

2024年4月6日 Cone crushers are a type of compression crusher used by aggregate, coal, concrete, crushing, fracking sand, and mining industries, which reduces material by

More

JXSC provides a high-quality rock crusher cone machine, like the brands of Mesto and Nordberg. We also have other series crushing machines, such as jaw crusher, impact

More

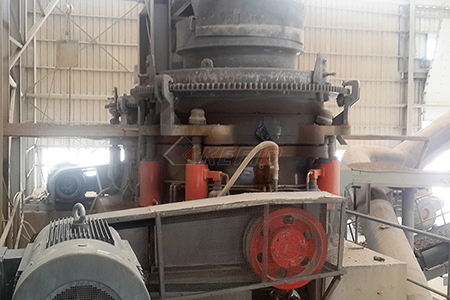

A cone crusher is a type of crusher that is commonly used for processing rocks in mining and aggregate applications. These crushers use compression force to break large rocks (and other materials) into smaller rocks, gravel and sand.. Since its inception, the live-shaft cone crusher design is highly regarded as the benchmark for reliable hard rock cone

More

Cone Crusher Cross-Section. The spring cone crusher design is able to pass uncrushable materials e.g. tramp metal, through the crushing cavity by using springs. The first hydraulic cone crusher was developed in 1948

More

5 天之前 When used correctly, cones will have a far lower operating cost than an impactor and produce less fines. The Powerscreen range of mobile cone crushers excel in a variety of applications from hard and abrasive rock to softer and more friable rock. The range uses advanced Automax® crusher technology to provide high volumes of excellently shaped ...

More

2020年6月4日 The size reduction process of rocks in cone crushers is one of the most important issues, particularly for the secondary and tertiary stages of crushing operations. In this study, 17 different rock types were considered for the evaluation of their size reduction variations that occurred in a laboratory-scale cone crusher. Based on several

More

Cone Crushers. Cone crushers are heavy-duty machinery suitable for crushing the stones into finished products. They can be used in various industries, including mining and construction. In addition to crushing materials, it can be used to help crush other materials such as ores and medium-hard rocks that require a great deal of pressure to smash.

More

Symons cone crusher 2ft ~ 7ft. Metso cone crusher HP3 ~ HP6. Metso cone crusher HP100 ~ HP800. Metso cone crusher GP11 ~ GP550. Metso MK Gyratory crusher S42-65 ~ S60-110. Metso MP800, MP1000, MP1250, MP2500. Sandvik cone crusher CH420 ~ CH890. Sandvik cone crusher CS420 ~ CS660. Terex TC1000, MVP380, MVP450, MVP550.

More

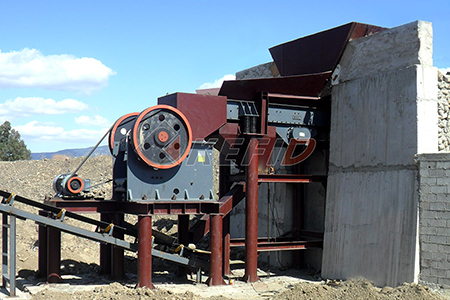

2023年8月2日 Eli Whitney Blake invented, patented, and sold the first actual rock crusher in 1858, it was known as the Blake Jaw Crusher. Blake’s crusher was so influential that today’s models are still compared to his original designs. ... Cone crushers are one of the main choices for secondary crushing. A cone crusher is a powerful machine that is ...

More

Nordberg® HP400™ cone crusher is a versatile rock crushing machine frequently utilized as a secondary, tertiary, or quaternary crusher in aggregates production or in mining operations. It is part of the world’s most popular cone crusher series, and designed for high productivity, low operating and wear costs, long service life and high ...

More

The controls of the CMB Cone Crushers comprise a contactless in-cylinder transducer and an operating console that can be positioned close to the crusher. Quick release, self-sealing couplings are used to connect the twin hydraulic hoses that run between the crusher and console. The console houses the fluid tank, motorized hydraulic pump, valves ...

More

Stone rock crushers are widely used in many sectors such as mining, smelting, building materials, highways, railways, water conservancy, and chemical industries.At present, there are two types of stone crushing

More

Sandvik cone crushers are an excellent choice in secondary, tertiary, quaternary and pebble-crushing applications. They are equipped with the hydraulic Hydroset™ system, which provides safety and setting-adjustment functions. Our crusher automation system delivers real-time performance management, enabling you to monitor and optimize

More

2020年6月23日 Cone Crushers were developed more than a century ago to provide secondary, tertiary and even quaternary material reduction.. Like other compression crushers, Cone Crushers feature a crushing chamber

More

Just call +90-312-397-91-33 and we will help you in any way we can. You can also send an e-mail to sales@mekaglobal, or fill in the inquiry form if you would like to pass us a detailed inquiry or project information. Use the Call Back option if you would like to be contacted by our sales team. MEKA cone crushers are an excellent choice as ...

More

They can be adapted to different applications. This is an important factor, as client-specific needs often change during a crusher’s lifetime. For cone crushers there are few rules to be followed of optimum cubical shape. These ‘Ten Golden Rules’ are: Full crushing chamber. This means that cone head must be covered by rock.

More

Marcy ® Lab Cone Crusher is ideal for reducing aggregates and mineral ores. The Marcy ® GY-Roll 6in (152mm) or 10in (254mm) Lab Cone Crushers have 300lb per hour (136kg) or 600lb per hour (272kg) throughput capacity. The throughput rate is dependent upon the material crushed; with coarser settings, the throughput capacity may be higher.

More

5 天之前 Construction aggregate is typically medium or coarse materials like granite, limestone or trap rock, sand, gravel, slag or recycled concrete. Processing this material may include reducing its size with a crusher, sizing the crushed material with a screen and conveying the material into different stockpiles. ... Titan-Cone-Crusher-T400-Spec ...

More

2019年7月3日 reducing the size of rock particles. Cone crushers utilize this mechanism and are the most widely used type of crusher for secondary and tertiary crushing stages in both the aggregate and mining industry. The cone crusher concept was developed in the early 20th century and the basic

More

Max. feed size. 214 mm (8 in.) Capacity. 220 mtph (242 stph) Sandvik QH332 is a tracked, self-contained cone crusher designed for versatility, safety and high performance. Featuring the Sandvik Hydrocone crusher, it comes with a number of features to ensure maximum uptime and minimum operator intervention.

More

2024年4月22日 Width: 13'5" Length: 51'10" Height: 17'1" / Width: 4.1m Length: 15.8m Height: 5.22m. Weight. Tier 3: 94,578lbs Tier 4: 94,799lbs / Tier 3: 42,900kg Tier 4: 43,000kg. The Powerscreen 1150 Maxtrak is a medium sized tracked cone crusher which has been designed for direct feed applications without pre-screening on clean rock.

More