Ball mill. Planetary ball mill is used for fine grinding of hard, soft, brittle and tough metallic, ceramic and composite materials. It can also be used for mixing and homogenization of

More

2019年5月31日 Design of a Horizontal Ball-Mill Reactor and Its Application in Dimerization of Natural Fatty Acids. Xianghong Lu*. Zhihe Wang. Dongdong Hu. Xiao Liang. Jianbing

More

Tumbling ball mills or ball mills are most widely used in both wet and dry systems, in batch and continuous operations, and on small and large scales. Grinding elements in ball mills

More

Application of the equipment/machine: This machine is ideally suited for loss-free grinding down to a final fineness of 100nm of hard, medium-hard and brittle materials. Depending

More

CE Certified Insmart Planatery Ball Mill (PBM) is ideal for analytically pure and contamination free batch grinding of test samples in dry as well as in suspension from as

More

A ball mill consists of various components that work together to facilitate grinding operations. The key parts include the following: Mill Shell: The cylindrical shell provides a protective

More

Ball mills are usually either of the grate (diaphragm) or overflow type. Ball Mill Components. Ball mills consist of the following components: Inlet – crushed ore is fed to the ball mill

More

2023年1月30日 Company Profile. MIKRONS® group is one of the leading manufacturers and suppliers of the Chemical Plant Machineries for varied industries under the brand

More

Find here Ball Mills, Laboratory Grinding Mill manufacturers OEM manufacturers in India. Get Contact details address of companies manufacturing and supplying Ball Mills,

More

Business listings of Ball Mills, Laboratory Grinding Mill manufacturers, suppliers and exporters in Mumbai, बॉल मिल विक्रेता, मुंबई, Maharashtra along with their

More

A ball mill consists of various components that work together to facilitate grinding operations. The key parts include the following: Mill Shell: The cylindrical shell provides a protective and structural enclosure for the mill. It is often made of steel and lined with wear-resistant materials to prolong its lifespan.

More

We have a strong production capability to manufacture ball mill accessories according to the PDF or CAD drawings provided by customers. If you have any needs, please contact us! Ball mill cylinder, ball mill end cover, ball mill grinding media, ball mill lining plate, and ball mill girth gear are five must-know ball mill spare parts.

More

2022年11月30日 A ball mill also known as pebble mill or tumbling mill is a milling machine that consists of a hallow cylinder containing balls; mounted on a metallic frame such that it can be rotated along its longitudinal axis.

More

We are An ISO-9001:2015 Certified Company call: +91-9827113763 for wide range of Ball Mill Manufacturers Suppliers in Hyderabad Telangana India.

More

Crushed ore is fed to the ball mill through the inlet; a scoop (small screw conveyor) ensures the feed is constant. For both wet and dry ball mills, the ball mill is charged to approximately 33% with balls (range 30-45%). Pulp (crushed ore and water) fills another 15% of the drum’s volume so that the total volume of the drum is 50% charged.

More

2 天之前 HOME > PRODUCT > Ball Mill / 볼밀 UBM-100S UBM -100S Roller size : Ø50 x 300mm Roller Material : Crown Urethane Roller UBM-100L UBM-100L Roller size : Ø70 x 750mm Roller Material : Crown Urethane Roller ...

More

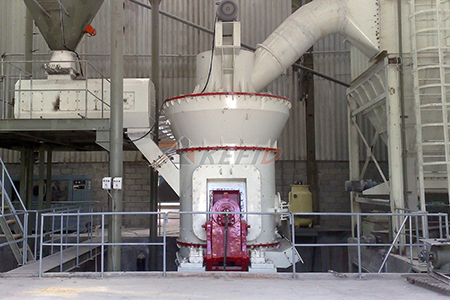

2021年7月16日 Ball mill is mainly used for grinding in mining (metallic minerals and non-metallic minerals), cement, refractories, chemical, power plant, aluminum, building material, glass, ceramic, steel slag and fly ash, ect.It follows more crushing and less grinding principle to save energy. The feed size to ball mill shall be smaller than 25mm, the output size can

More

Ball Mills is a key equipment to grind the crushed materials, and the ball mill is widely used in powdermaking production line including cement, silie, newtype building material, refractory material, fertilizer, ore dressing of ferrous metal and nonferrous metal, glass ceramics, etc.

More

Quantum Nanostructures (QDs): An Overview. D. Sumanth Kumar, ... H.M. Mahesh, in Synthesis of Inorganic Nanomaterials, 2018 3.6.1.1 Ball Milling. A ball mill is a type of grinder used to grind and blend bulk material into QDs/nanosize using different sized balls. The working principle is simple; impact and attrition size reduction take place as the ball

More

2024年4月4日 USA Headquarters FRITSCH Milling and Sizing, Inc. 57 Grant Drive, Suite G Pittsboro, NC, 27312. Phone + 1 919 229 0599 Email: info@fritsch-us.

More

المصنعين الطاحن في الهند المصنعين مطحنة الأسمنت في الهند. كرات طحن في الكرة المصنعين مطحنة. Ball mill Wikipedia. A ball mill is a type of grinder used to grind and blend materials for use in mineral dressing The ball mill is used for grinding materials such as coal pigments and feldspar for

More

الصانع مارسي الكرة مطحنة الهند (99+ مراجعات العملاء) مطحنة لفة اثنين من مصنعي فيالكرة مطحنة مصنعين في سري لانكا,تبوك في الكرة مطحنة Leeuw-design الرمادي الكرة مطحنة مصنعين في الهند أكYouTube.

More

Ball Mill. The proven classical option for cement grinding. Whether employed as a two-compartment separator mill in an independent grinding system, or in combination with a high pressure grinding roll, the Ball Mill is a robust and reliable alternative for cement and granulated blast furnace slag grinding. Used in combination with the sepol ...

More

FabTech Manufacturers Ball Mill, Continuous Type Ball Top Ball Mill Manufacturers Company in India, Continuous Type Ball Mill manufacturer Gujarat, Quartz Gri. Address: No.169, Science (Kexue) Avenue, ball mills manufacturer in gujrat 0729T00:07:40+00:00

More

4 天之前 TITAN BALL MILLS. Based on the MPT TITAN™ design, the Mills are girth gear dual pinion driven with self-aligned flanged motors, running on hydrodynamic oil lubricated bearings. The TITAN design enables you to run full process load 40% Ball charge at 80% critical speed – Max grinding power for every shell size. Standard Mill Types Available:

More

We are Ball Mill, Pulverizer Manufacturer in Hyderabad Telangana. pulverizer pulverized materials and ball mill grind the process materials Phone : +91-9827113763 +91-7587733050 Home

More

Planetary Ball Mills. Sample volumes up to 4 x 220 ml. Final fineness*: 0.1 µm. Extremely high centrifugal forces result in high energy input. Dry and wet grinding by impact and friction. To the product range. Ultrafine grinding with up to 76 g.

More

Warranty. 1 Year. Country of Origin. Made in India. The Lab stirred Ball Mill is primarily intended for the grinding of pigments. The material is ground at a specific speed and for a specific period of time using a specific quantity of grinding media (steel balls). The equipment is used in the laboratory to create ground cement samples.

More

2019年1月1日 BALL MILL 1 KG. Ball Mill 1 kg Motor Driven Heavy Duty with 10 Big Stainless Steel Balls (15 mm) and 35 Small Stainless Steel Balls (8 mm) Also Called Laboratory Ball Mill is used for preparation of samples for analysis with minimum loss of moisture of volatile constituents. Weight distribution and balancing of rotating parts has

More